Commercial Restaurant Fit-Out Estimation and Visual Mapping – Fredericksburg, VA

Location: Fredericksburg, Virginia

Service Category: Restaurant Interior Build-Out | Commercial Estimation | Fixture Mapping | Permit Strategy

Overview

When approached to support a new restaurant build-out project in Fredericksburg, Unified Studio Architect was tasked with creating a highly detailed, visually clear, and code-informed construction estimation for a commercial kitchen and service area.

This case study outlines the exact steps we followed—making it an excellent reference for restaurant owners, franchisees, or developers planning a food service fit-out. By showcasing how we translated a conceptual layout into an actionable set of documents, this case helps you envision how your own project could be approached, estimated, and built with clarity and confidence.

Step 1: Reviewing Concept Layout & Initial Inputs

Every successful build-out starts with understanding the space and vision. The client provided a rough plan markup showing where kitchen equipment, fire extinguishers, gas points, and sanitary fixtures would be located.

Our first action was to conduct a feasibility review, where we:

- Verified the scale, layout, and space programming

- Identified the kitchen zoning (hot cook line, prep, wash, storage, dish area)

- Highlighted critical areas like egress paths, handwashing station compliance, and ADA-accessible restroom fixtures

We used this phase to flag missing details early—ensuring what gets estimated later has a foundation in real-world constructability and compliance.

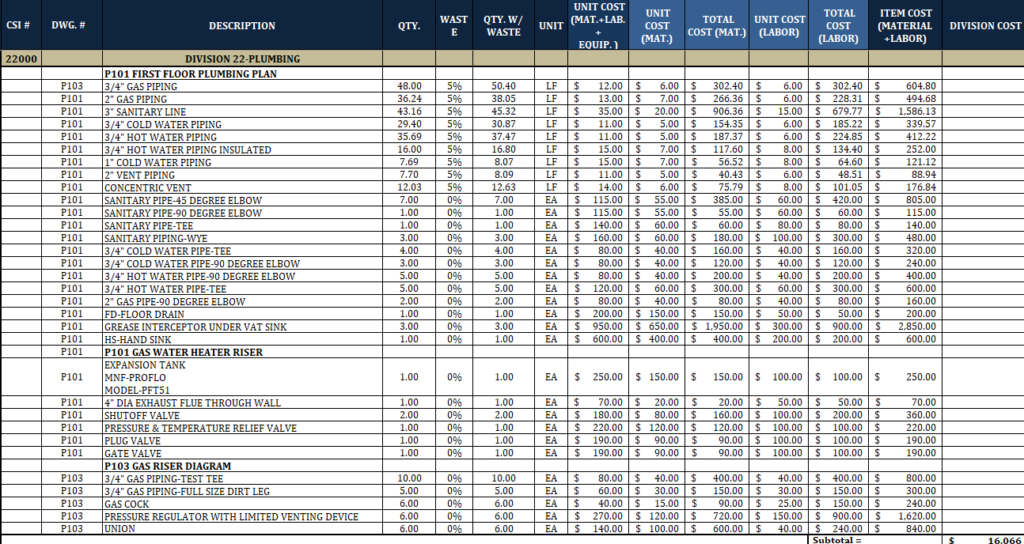

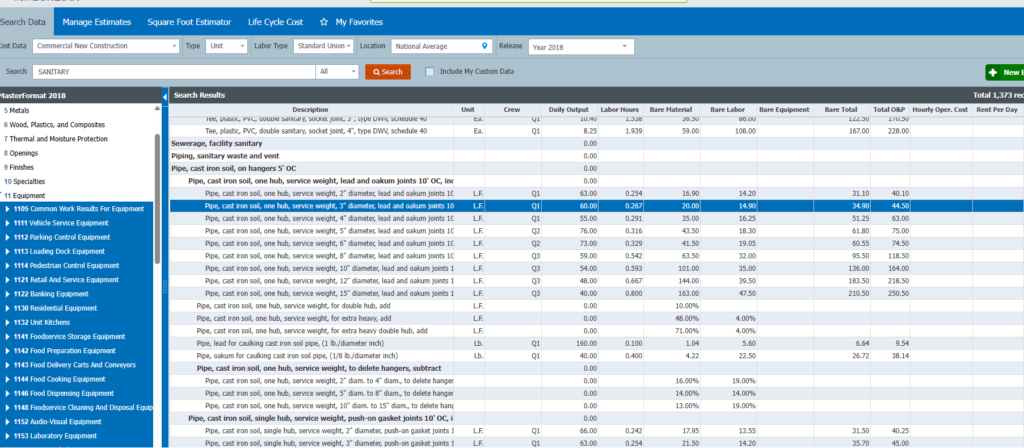

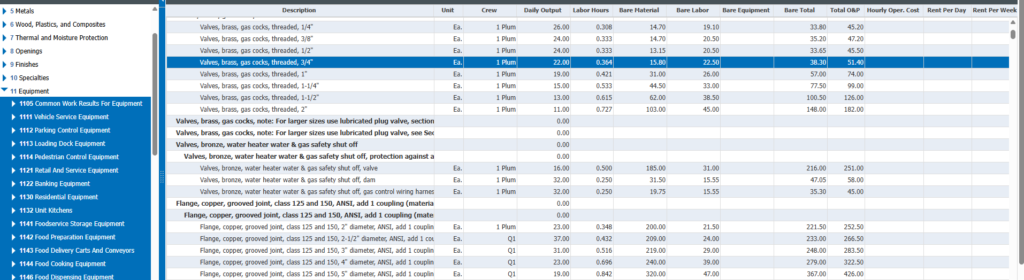

Step 2: Categorizing Fixtures and Equipment Requirements

To move from vision to execution, we needed to translate the concept into quantifiable elements. We created categories based on the core systems:

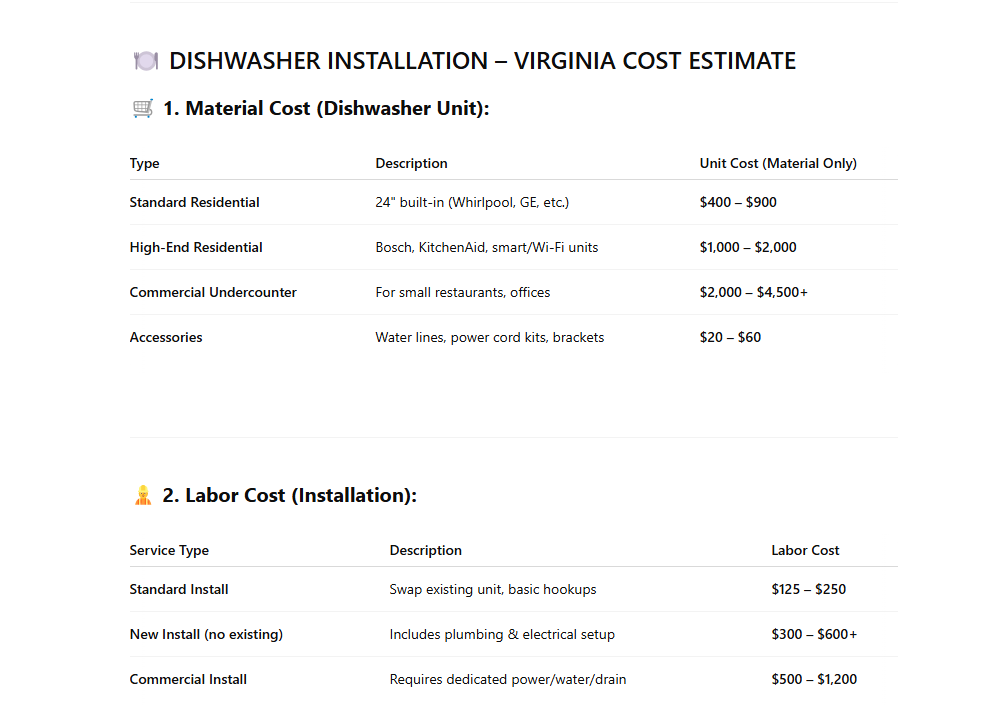

- Kitchen Fixtures (e.g., sinks, prep tables, ovens, hood)

- Gas and Utility Connections

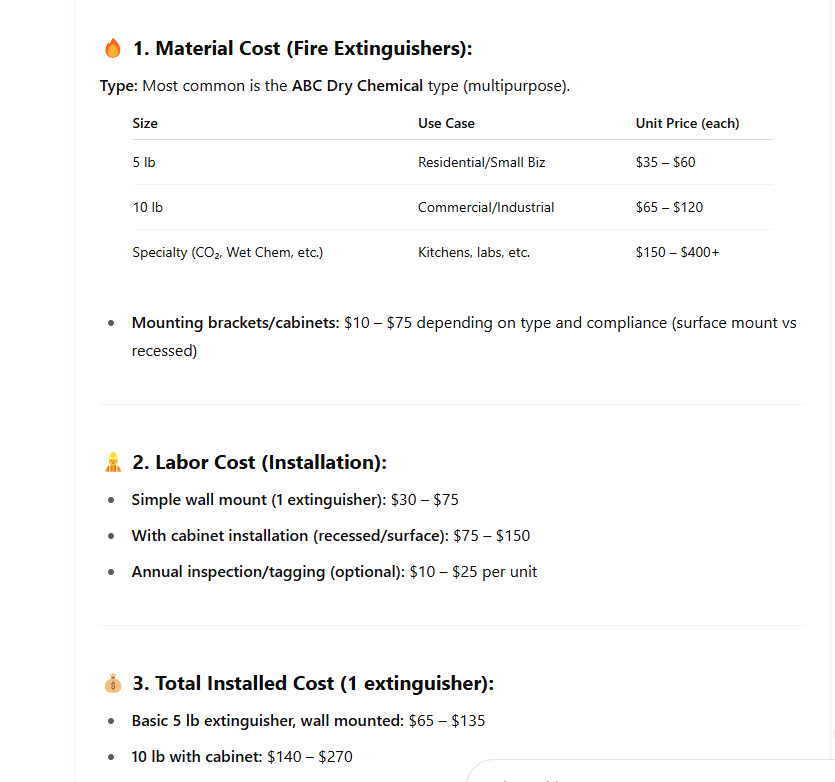

- Fire Protection Equipment (e.g., Class K extinguishers)

- Plumbing Fixtures (e.g., floor sinks, handwash stations)

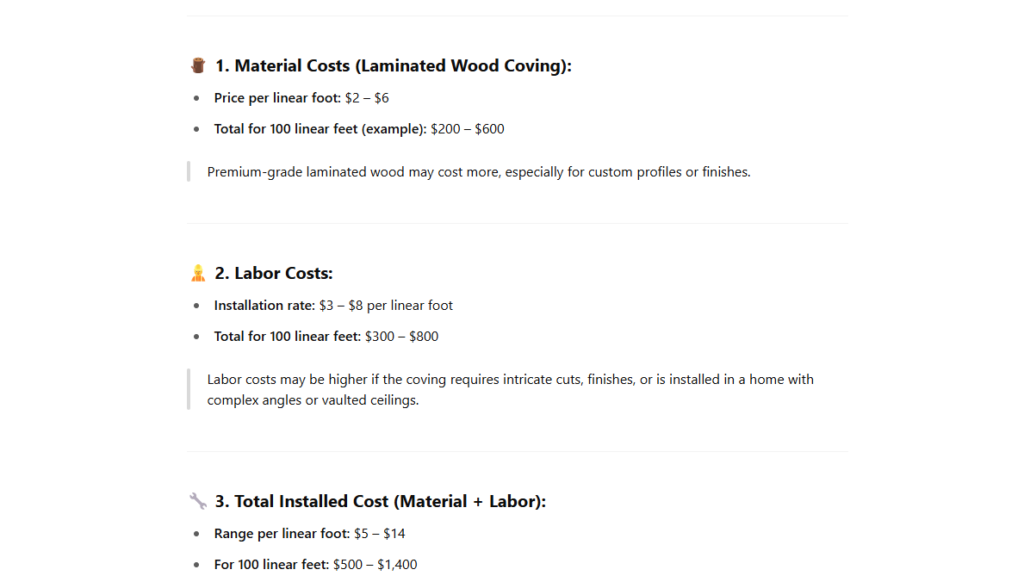

- Coving and Hygienic Wall Systems

We used labeled markups and layers to organize each system, ensuring visual clarity. These groupings helped contractors easily assign responsibilities across trades, from plumbing to electrical to fire protection.

Step 3: Creating Visual Reference Sheets for Field Teams

Typical estimation tables can be hard to decode. To solve this, we introduced a graphic-based estimation model. For each fixture or component, we created visual reference sheets with:

- The labeled item location on plan

- A clear product-type image or symbol (e.g., for dishwashers, extinguishers, gas cocks)

- Notes on installation context and proximity to services

This method ensured that even non-technical stakeholders—owners, field installers, or equipment suppliers—could immediately understand what’s needed where. It reduced back-and-forth queries and improved site coordination.

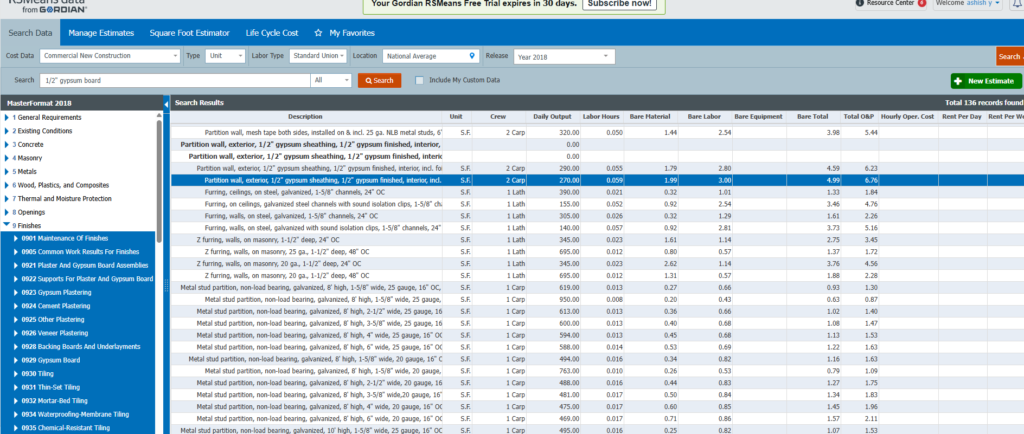

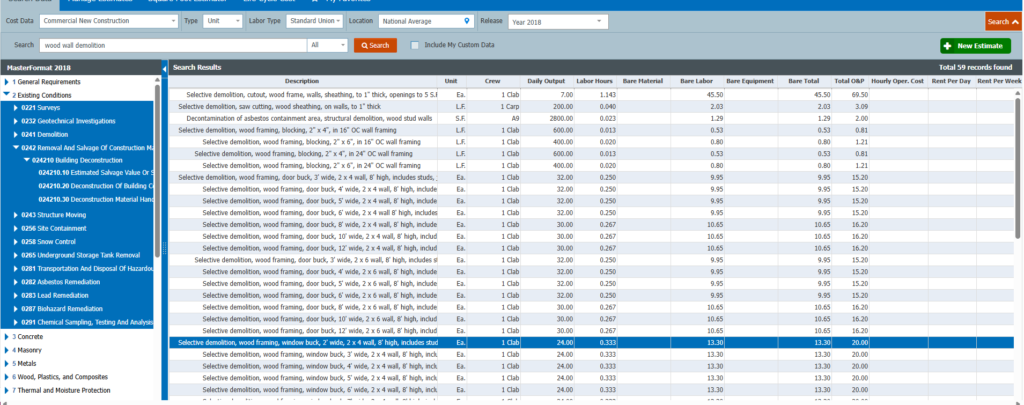

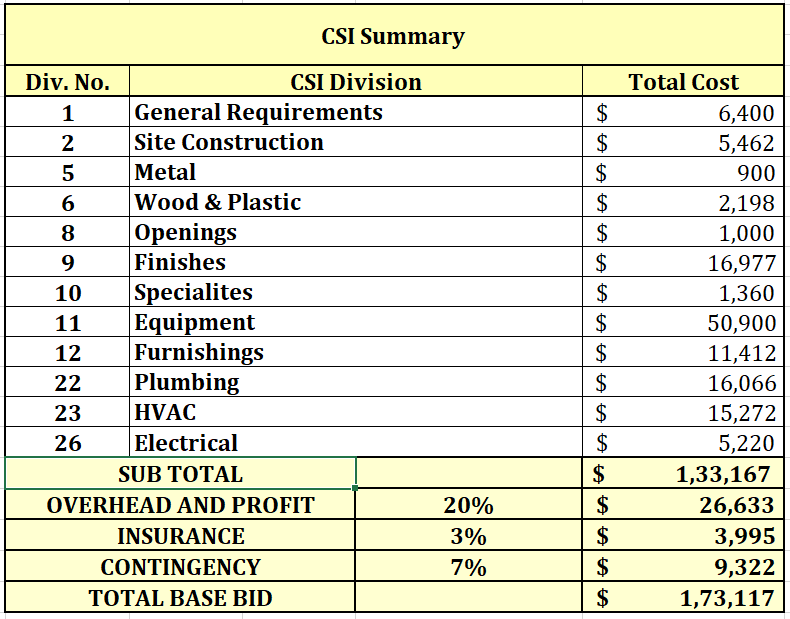

Step 4: Generating the Master Estimation Table

We then compiled a detailed Excel-based estimation table structured as follows:

| ID | Description | Quantity | Unit | Area | Notes |

|---|---|---|---|---|---|

| DW-01 | Commercial Dishwasher | 1 | unit | Kitchen | Requires floor sink & wall-mounted faucet |

| SAN-02 | Handwash Sink | 2 | unit | Near cook line & restroom | ADA height verified |

| GAS-04 | Gas Cock for Range | 3 | unit | Rear wall | Tag with 3/4” line routing |

| EXT-01 | Class K Fire Extinguisher | 1 | unit | Near cooking area | UL-listed per kitchen safety code |

| COV-01 | PVC Coving | 24 | feet | All wall edges | 4″ radius, hygienic wall-to-floor transitions |

This structure makes it easy for:

- Contractors to bid and schedule based on categories

- Suppliers to provide accurate quotes

- Owners to plan purchases ahead of construction

Step 5: Identifying Code-Triggered Items

Our team flagged all elements that could trigger permit scrutiny or health code violations. This included:

- Handwash sink spacing and proximity

- Wastewater connections with air gaps

- Location of gas shut-offs in relation to appliances

- Fire suppression requirements under Type 1 hoods

- Slip-resistant floor transitions and cove base application

We noted each trigger clearly in the estimation table, acting as a built-in compliance guide. This proactive step is what saves time and money during plan check or health inspection.

Step 6: Drawing Integration for Permitting & Coordination

Although our scope was focused on estimation and coordination, our team ensured alignment with architectural permit drawing standards.

We cross-referenced each fixture and system with potential:

- Utility stub-out locations

- Floor plan room names

- Mechanical hood and exhaust routing zones

- Accessible path and service counter heights

This ensured a seamless handoff when our estimation was integrated into future permit drawings—by us or any third-party architect.

Step 7: Deliverables Shared with Stakeholders

We delivered the following:

- Visual Fixture Reference Set

- Including separate sheets for:

- Gas fixtures

- Sanitary and plumbing equipment

- Kitchen dish line

- Fire extinguisher placement

- Wall coving edges

- Including separate sheets for:

- Excel-Based Estimation Table

- Structured with clear IDs, quantities, units, and construction notes

- Code Trigger Advisory Sheet

- Quick summary of all elements requiring jurisdictional compliance

These documents were shared with the restaurant owner, GC, kitchen equipment supplier, and MEP teams for coordination.

Why This Matters to Your Restaurant Project

If you’re building or remodeling a restaurant space, our workflow ensures you’re not just estimating blindly. We:

- De-risk your permits by flagging code elements early

- Empower your vendors with precise visuals and scope

- Save your budget from bloated or inaccurate estimates

- Help your contractor build faster by knowing exactly what goes where

You’ll get to construction quicker, with fewer surprises.

Key Takeaways for Owners and Builders

Here’s how this case study serves as a reference for your own fit-out project:

| Objective | How We Helped |

|---|---|

| Organize Fixture Layout | Used system-based grouping (dish, gas, fire, plumbing) |

| Speed Up Estimating | Delivered Excel table with install notes and quantities |

| Improve Coordination | Shared labeled visuals for easy trade handoff |

| Flag Permit Issues Early | Highlighted code-sensitive components before plan submission |

| Simplify Field Work | Gave installers an image-based reference to minimize confusion |

Future-Ready and Scalable

While this project was for a single-location kitchen, our system is fully scalable. Whether you’re fitting out:

- A fast-casual food chain

- A bar and grill concept

- A franchise prototype kitchen

Unified Studio Architect can scale the same clarity, code compliance, and contractor-ready deliverables for multiple sites—nationwide.

Final Thought

From the first markup to the final deliverable, we focused on precision, communication, and compliance. Unified Studio Architect delivers more than drawings — we help owners translate vision into viable construction, with confidence and speed.

If you’re planning a commercial restaurant or kitchen build-out, our process ensures you get exactly what you need—nothing missed, nothing vague.

Explore more of our restaurant and food-service architectural support services.

Let’s talk about your next project.